Select High Quality Materials

Dispenser Sump is made of high-strength engineering plastics /SMC composite materials, and its excellent material properties make the products available in all oil stations around the world.

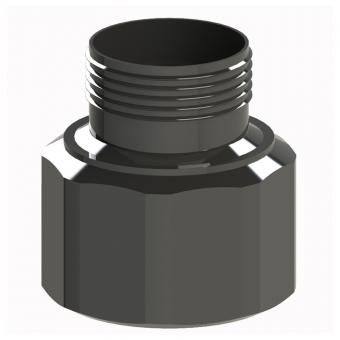

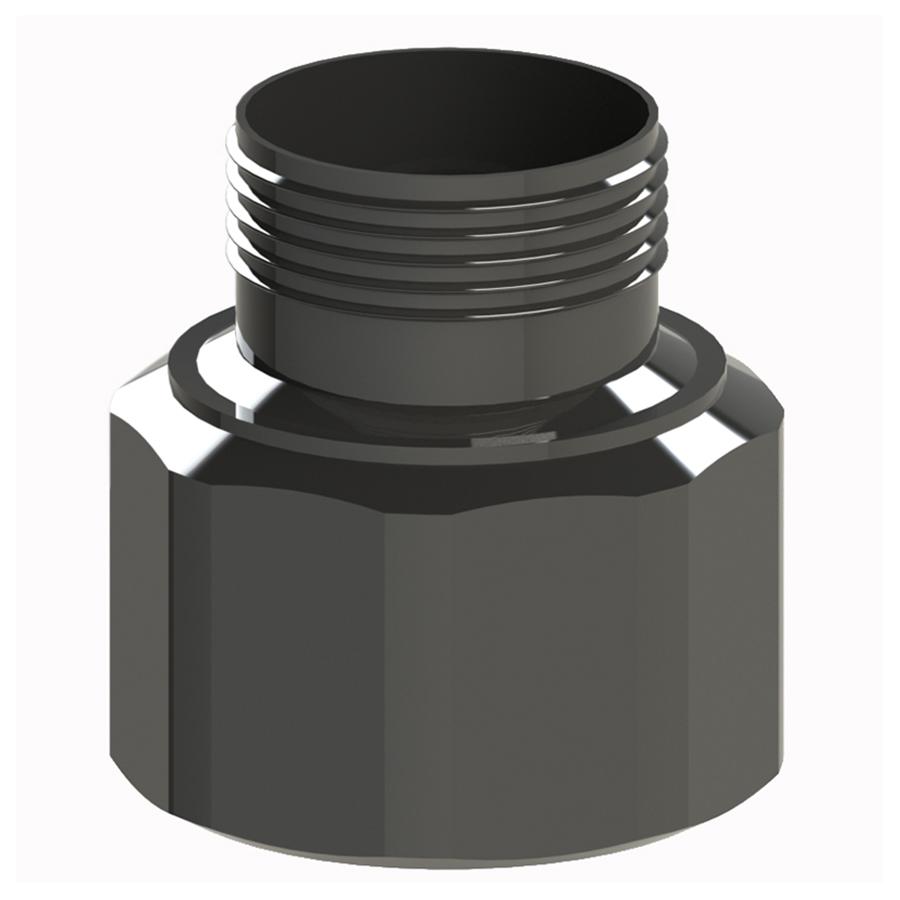

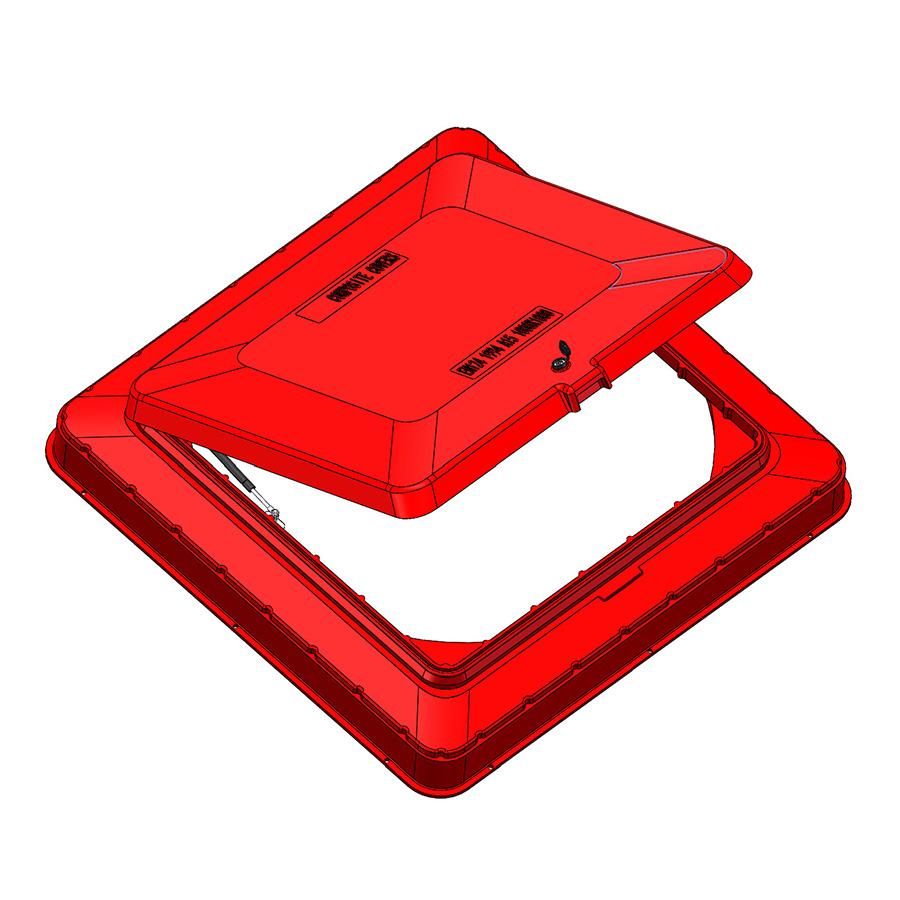

Convenient to use

The large operating space of Dispenser Sump makes the product more convenient to use.

A variety of inlet seals can be selected, so that the pipes entering and leaving the Dispenser Sump can be sealed, preventing groundwater from entering the Dispenser Sump and preventing soil pollution at the same time.

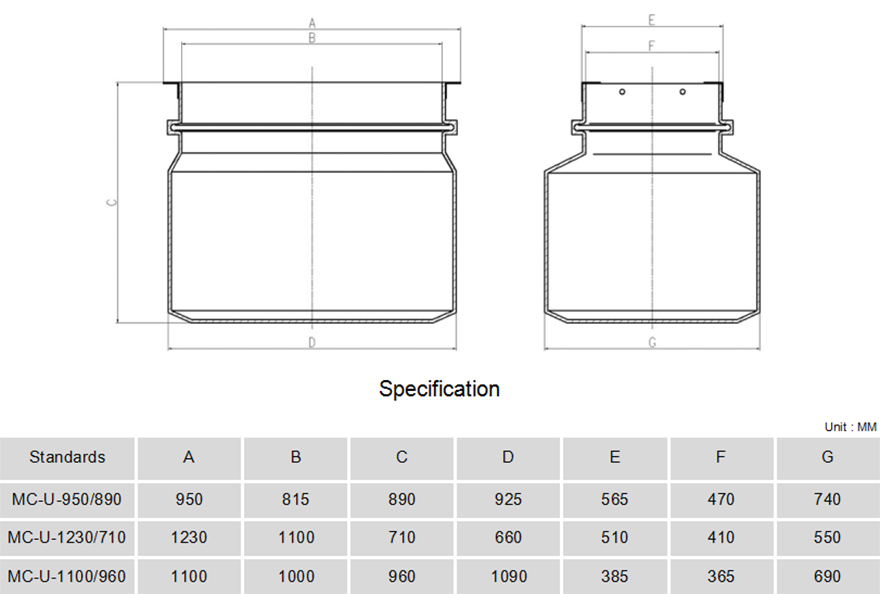

Well-designed

The size of Dispenser Sump is based on the design specifications of oil stations, which highly meets most of the use environments. Its height can be cut arbitrarily according to requirements, the reasonable size and material make cutting more convenient.