Select High Quality Materials

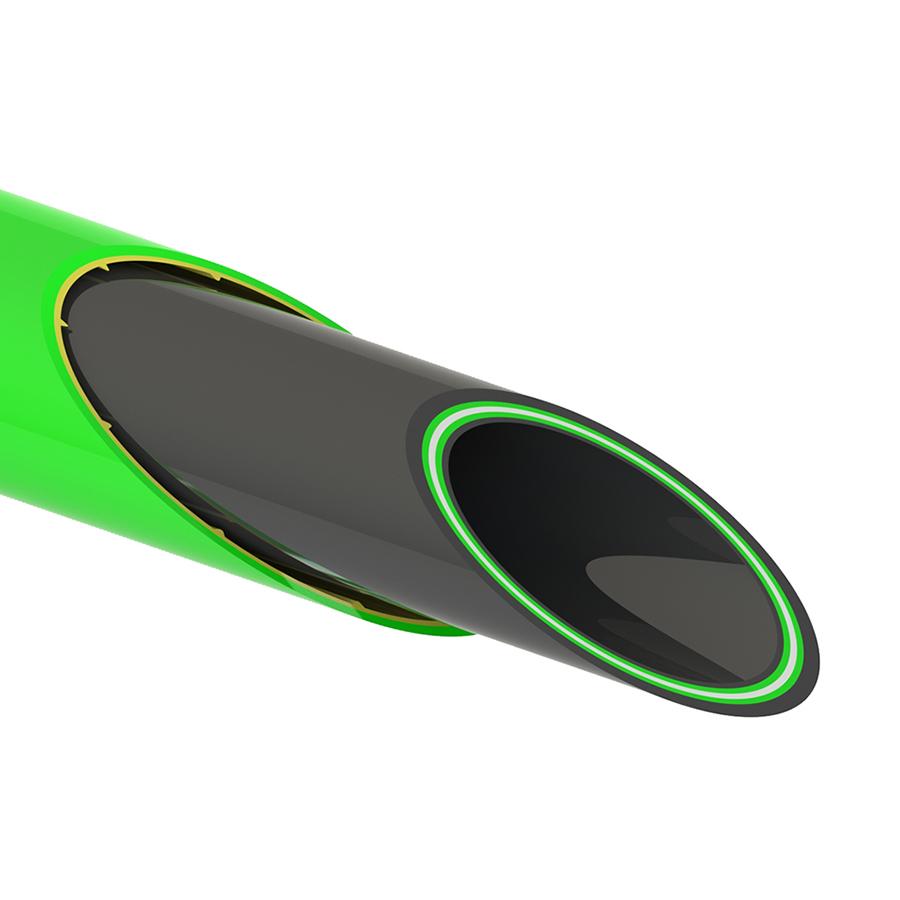

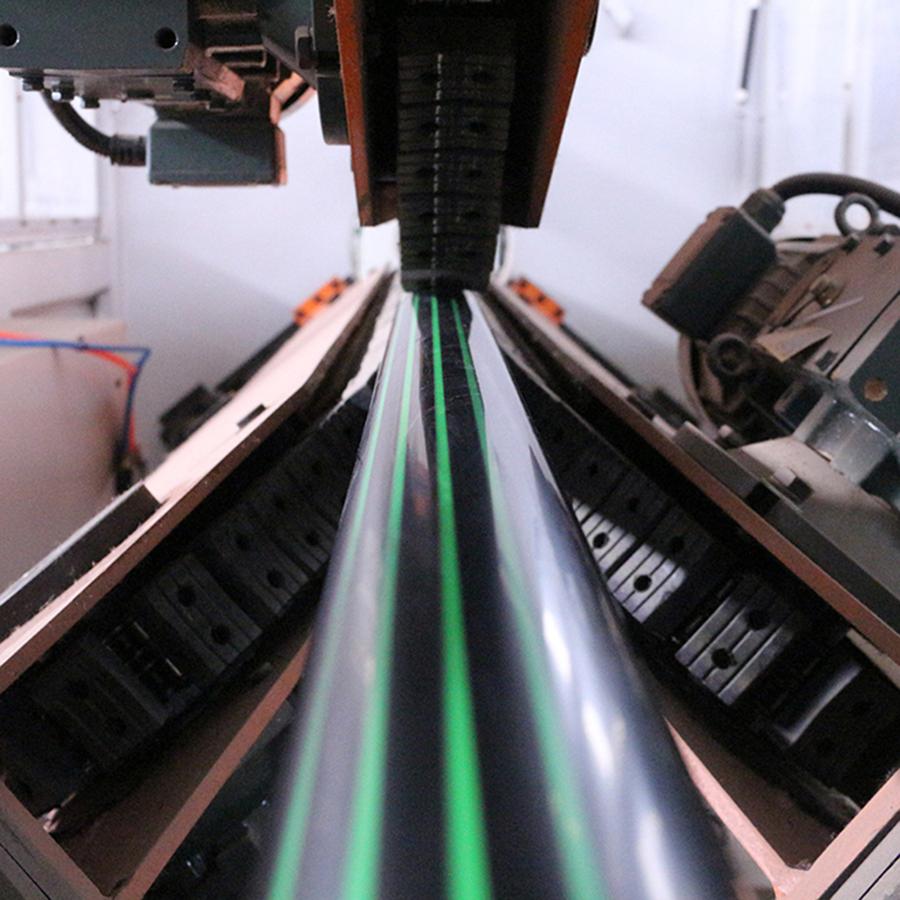

High-quality HDPE and EVOH are selected from international high-quality raw material manufacturers. The company has a complete IQC system, which strictly inspects the purchased raw materials, and at the same time, conducts regular and phased assessment on all suppliers. Excellent raw materials ensure that the fuel permeability of the product is "0", the bursting pressure is above 2.5Mpa, and the stability of product quality is extremely high.

Due to the excellent material performance of M & C Pipework , the fuel pipeline works in the operating temperature range of 40℃ to 50℃, with almost zero leakage and its burst pressure exceeding 25 standard atmospheric pressure (bar), thus maintaining the safety of product use.

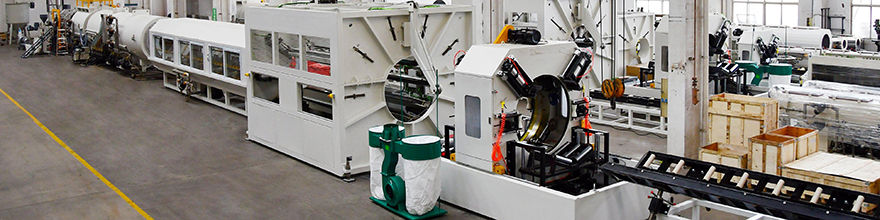

Advanced Technology

M & C always insists on taking science and technology as the forerunner, taking market as the guide, paying attention to scientific and technological input, improving independent innovation ability and accelerating product technological innovation. We have invested large money in research and development funds, cooperated with universities and design institutes for long-term production, education and research, and established an independent innovation platform. We set up the relevant engineering technology center for product research, development and equipment improvement.

Complete Product Categories

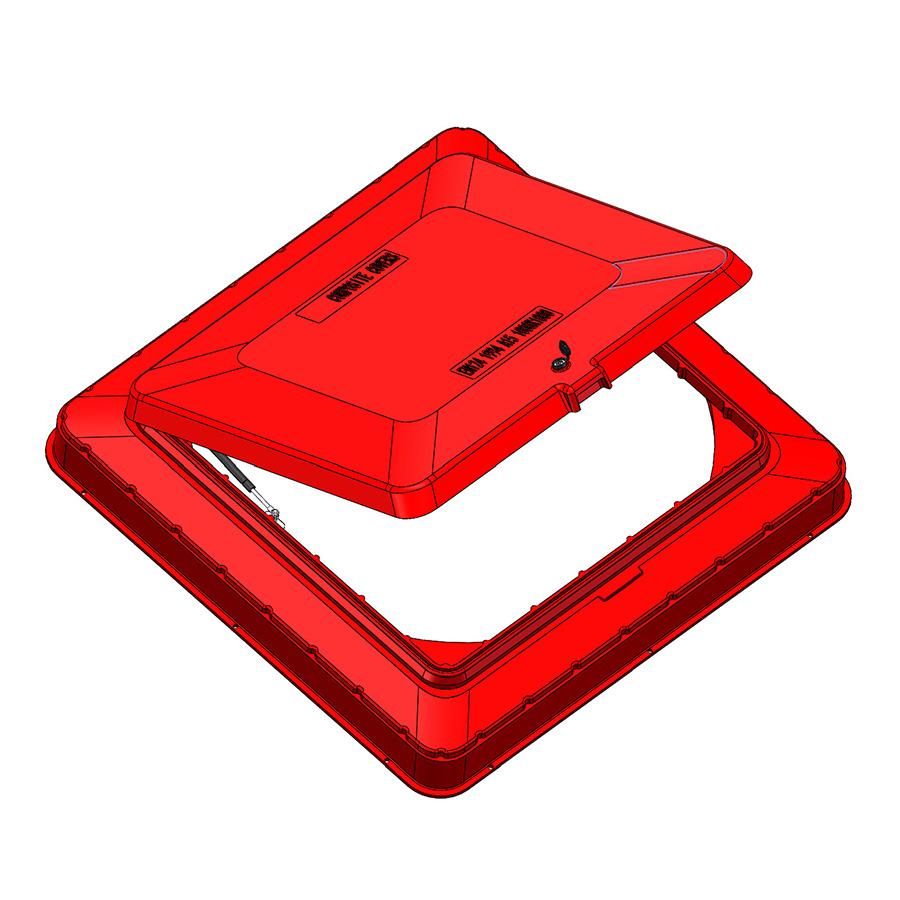

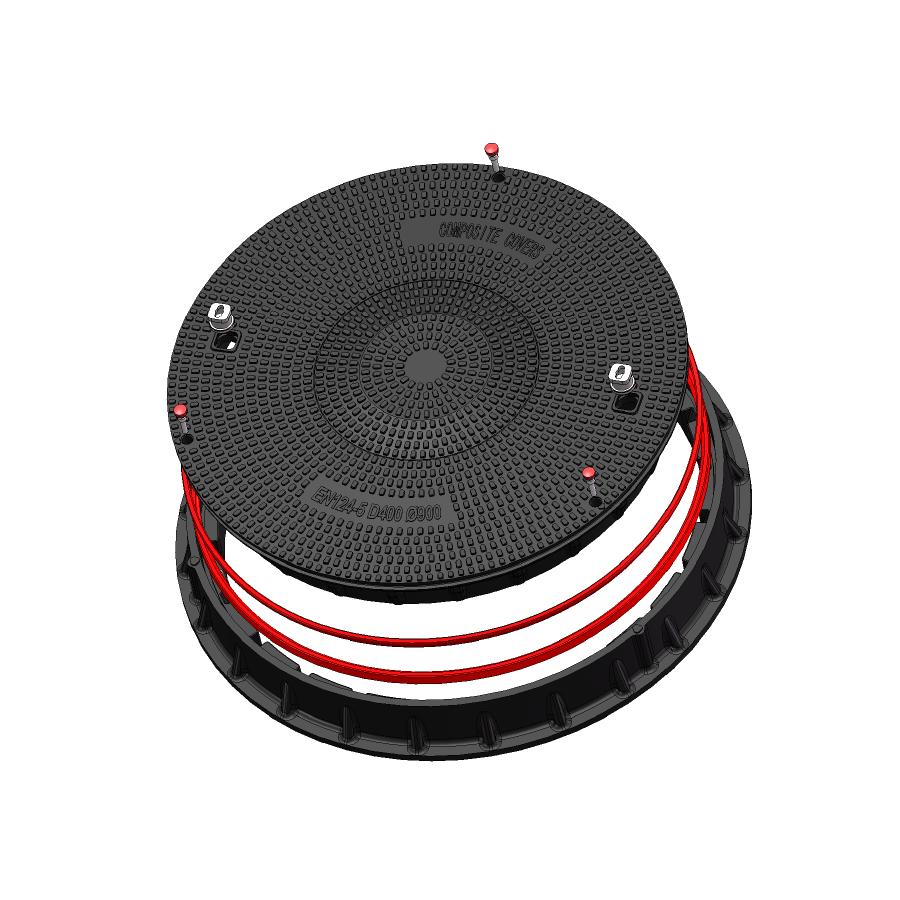

The products meet all use requirements of relevant scenes in the oil station system. 65/54, 75/63, 110/125 double-layer composite pipework and 54, 63, 90 , 110 single-layer composite pipelines cover all requirements of oil transportation, oil unloading, breathing pipelines and oil vapor recovery pipelines. At the same time, M & C team can also provide customized products and services for other demands generated by customers.

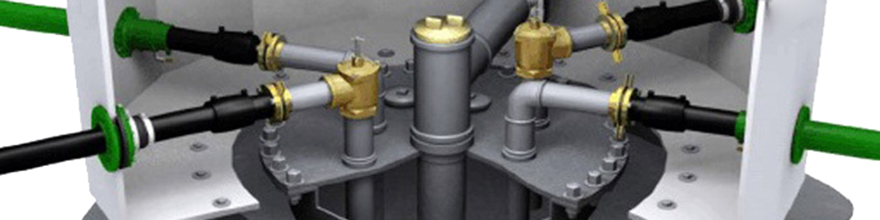

High Product Compatibility

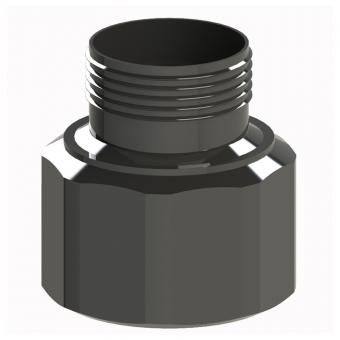

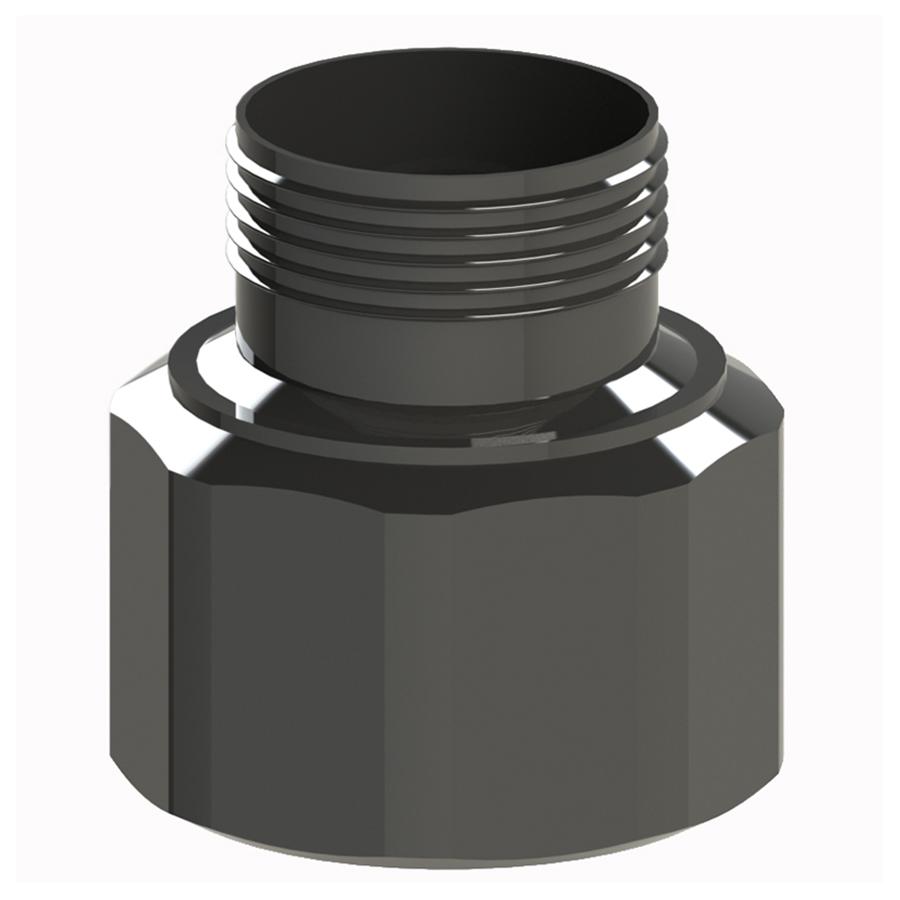

All specifications of products can be butted with tank sumps and dispenser sumps, and special inlet seals can ensure the tightness of product joints. Seals are made of silicon-fluorine compound rubber, which meets the characteristics of low temperature, oil vapor corrosion and aging resistance. Excellent design ensures the reliability and convenient installation of accessories.

M & C Pipework 's rich electric fusion welding fittings can conveniently change the direction and diameter of pipelines, and provide greater flexibility and control for pipeline layout. Use a good electrofusion welding process system to connect pipes and fittings to form a seamless directly underground installation pipeline engineering system, so that the impermeability and pressure strength of welded fittings are consistent with those of pipelines. It efficient and stable electrofusion welding system make the installation convenient and quick , and is suitable for installation under various complex working conditions.